Production Ergonomics

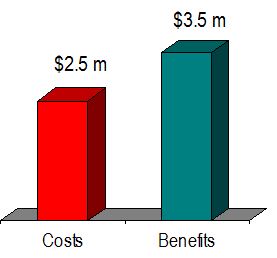

Costs and Benefits in Two Manufacturing Plants

Click here for a downloadable pdf copy of this page.

Plant 1:

|

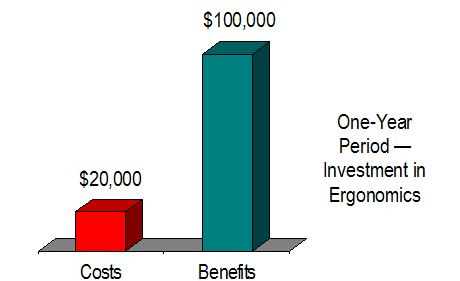

| 500% ROI in one year |

This example involved a machine shop of 60 employees where the insurance carrier cancelled the plant’s workers’ compensation policy because of the high number of musculoskeletal disorders. The plant was forced to turn to the state insurance pool with its extremely high premiums.

The ergonomic improvements were all very low cost (and some very innovative – see below) and the plant returned to normal insurance a year later. In some ways, this case example is atypical because the workers' compensation costs were horrendously high. Yet, these situations do exist, and undoubtedly companies fail every year because of the absence of good ergonomics.

Furthermore, there were productivity and quality gains that resulted from the improvements. By designing to make the jobs more human-compatible (that is, to prevent the wrist and arm disorders) the employees were put in a position of being able to do their jobs better.

Workstation Example 1

|

|

|

| Before: Left-hand manipulation | After: Potter's Wheel | Continuous improvement |

Deburring the parts was the source of most injuries, plus the defect rate was unacceptably high because employees had a difficult time doing the work effectively. The worst single job was dramatically improved by using a Potter’s Wheel as the basis for a fixture.

|

| 20% increase in productivity (and zero defects, zero injuries) |

The creative workstation yielded a 20% increase in productivity, while simultaneously both the injuries and defects dropped to zero. Ultimately, the engineers and machine operators (who previously had been unaware that deburring was causing injuries) found ways to eliminate the burrs in the machines and thus eliminated the root cause. See The Potter's Wheel for a more detailed description.

Workstation Example 2

|

|

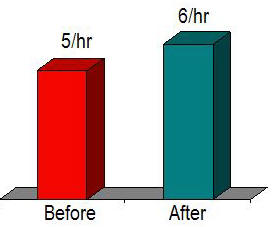

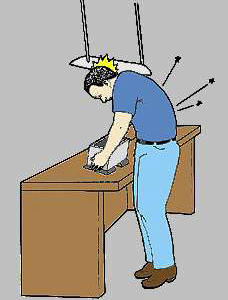

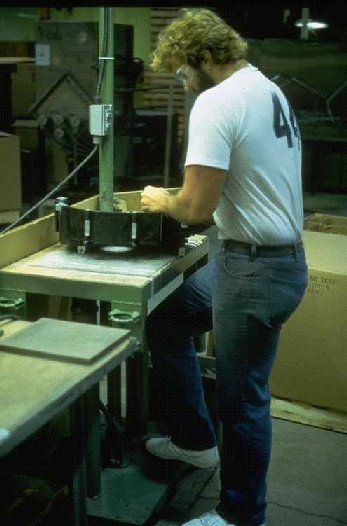

| Before: Generic work bench interfered with production | After: Tall employee working with ease |

Another set of deburring jobs in this plant were improved by using converted die carts for workstations to replace generic tables. The photo above shows a very tall, hard-working employee who previously had low production numbers because (a) his back hurt from constantly bending, and (b) the overhead light was in his way.

Using the die carts as adjustable, individual workstations furthermore opened the door to a continuous stream of good ideas. These features all improved the ability of employees to do the tasks more easily.

Quantitative before-and-after studies were not made for these individual tasks. However, the reduction in injuries and overall increases in efficiency are included in the plant-wide financial benefits.

The lessons learned during this project eventually evolved into How to design a workstation.

Plant 2:

|

| $1 million savings in 5 years |

This company of 1200 employees involves several paper mills and paper converting operations. The company was cited by OSHA for musculoskeletal disorders, paid a $300,000 fine, and was required to establish a formal ergonomics program. Fortunately, the company set up an excellent process that resulted in a $1 million savings over five years.

Much of this savings was in workers' compensation costs, but there were other cost reductions as well. The following are three examples of improvements where specific productivity improvements are known.

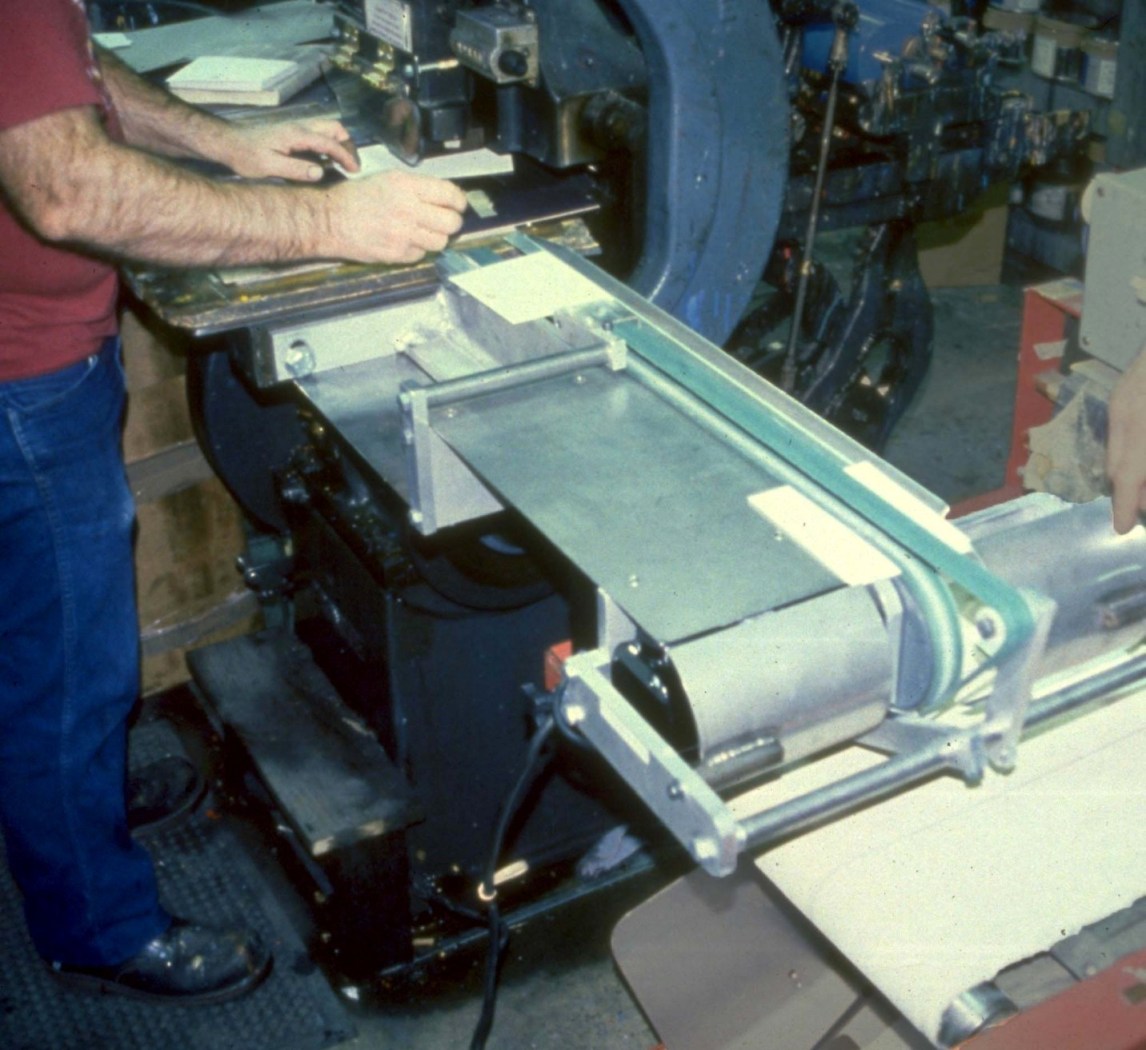

Mechanical flipper

|

|

| Before: Manual flipping | After: Mechanical flipping |

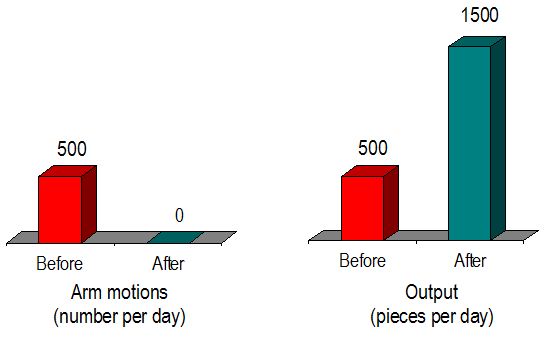

An example of one of the improvements at this facility were innovative mechanical flippers that were added to engraving presses that eliminated repetitive arm motions and freed the printers to perform other, more important tasks. The idea for the mechanical flipper came by adapting a mechanism on a large automatic press. As shown in the following graphs, arm motions were reduced to zero and productivity increased 300%.

|

| Arm motions reduced, output tripled |

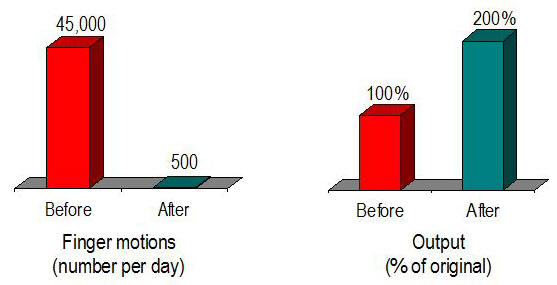

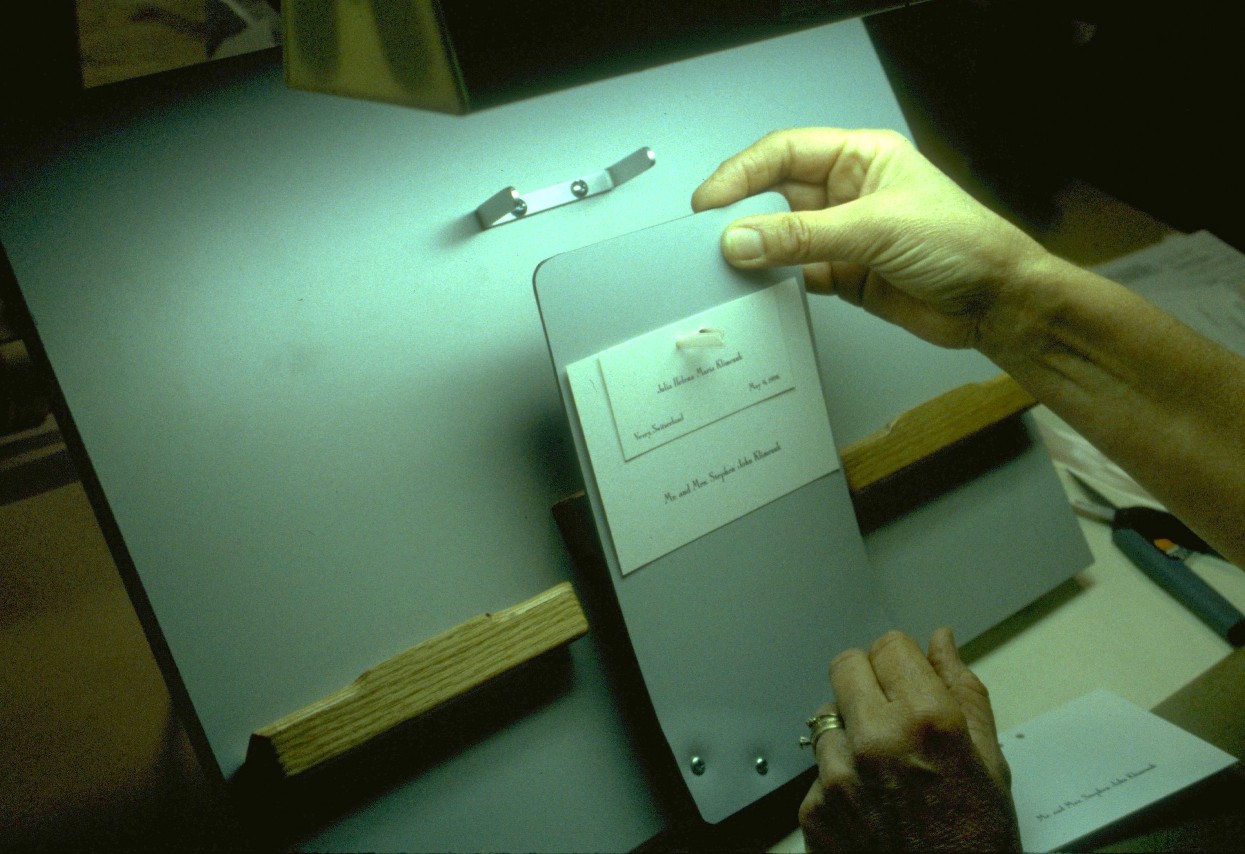

Page counter

|

|

| Before: Manually counting stack upon stack of paper | After: Workstation with lifts, paper counter, and air table |

The task involved counting stacks of folio-sized paper and inserting a slip sheet every 50th or every 100th sheet. The work involved 45,000 to 50,000 finger motions per day, mostly while working in awkward, static postures. “No one wanted to do this job.”

In this case, the employee took the initiative and on her own developed the plan to revamp the area. By recycling some used equipment and changing the layout, only a single piece of new equipment needed to be purchased. As a result, the time required to do the job was cut in half. The results are shown below, involving a payback period of about one year.

|

| Finger motions reduced, output doubled |

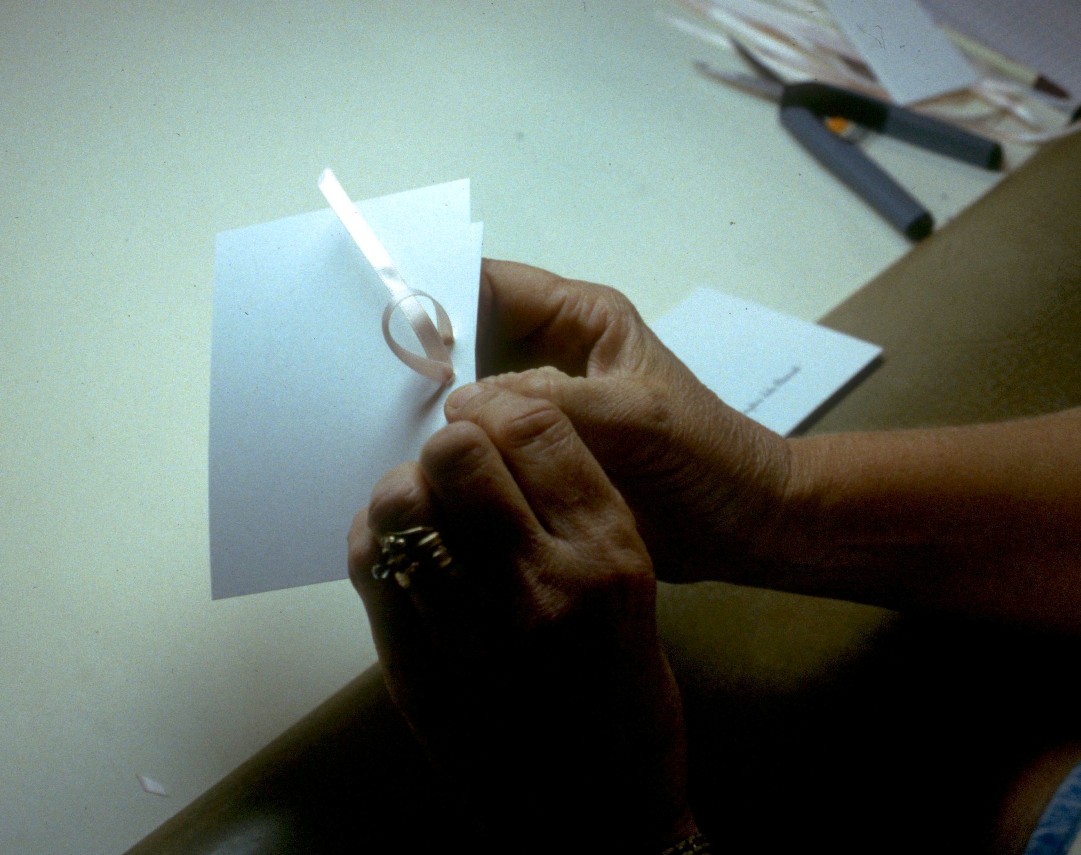

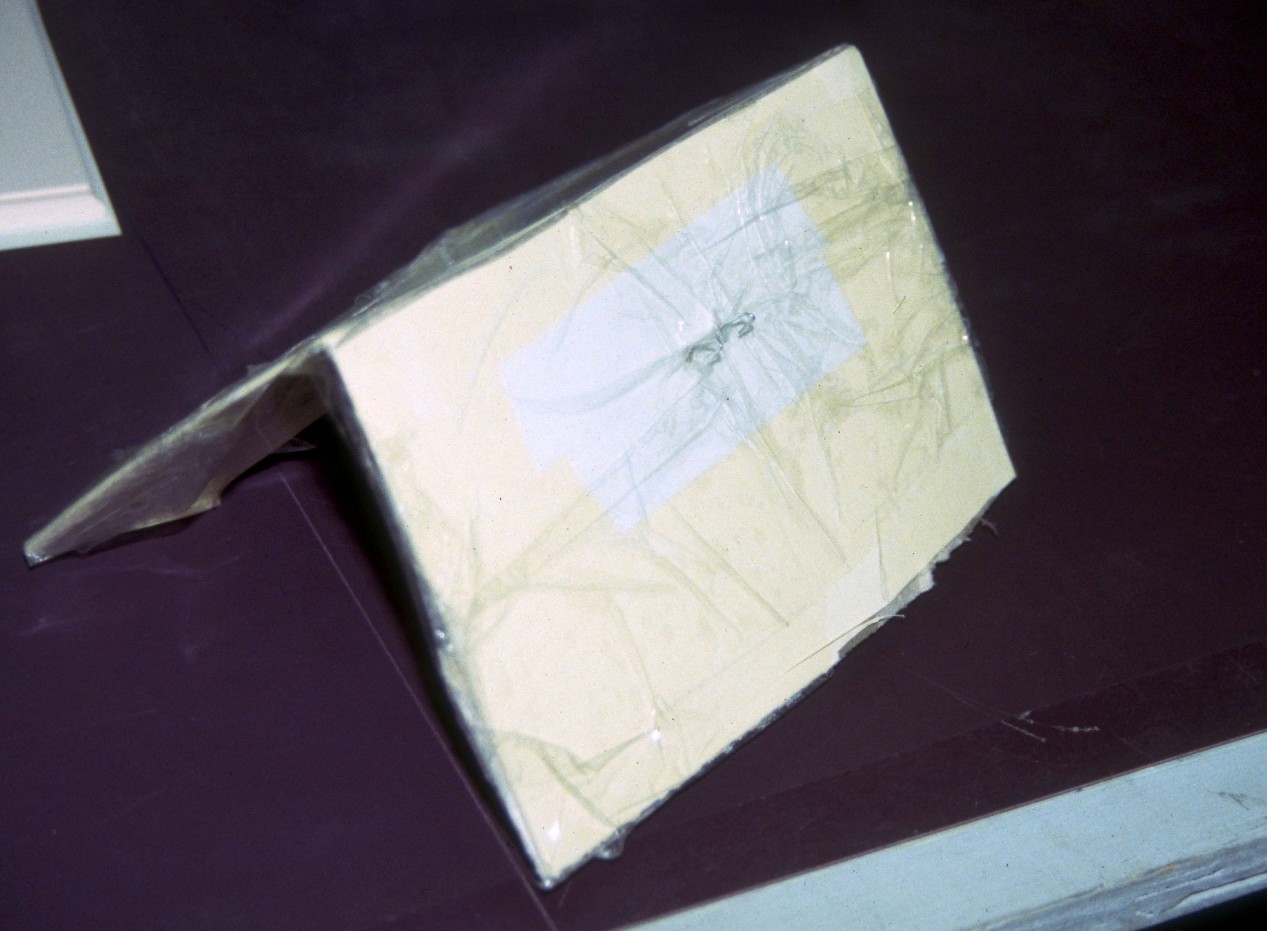

Employee invention: A ribbon tying device

|

|

|

| Before: Tying ribbons by hand | Employee’s homemade prototype: Paper clips, a manila folder, and clear tape. | After: A more polished device |

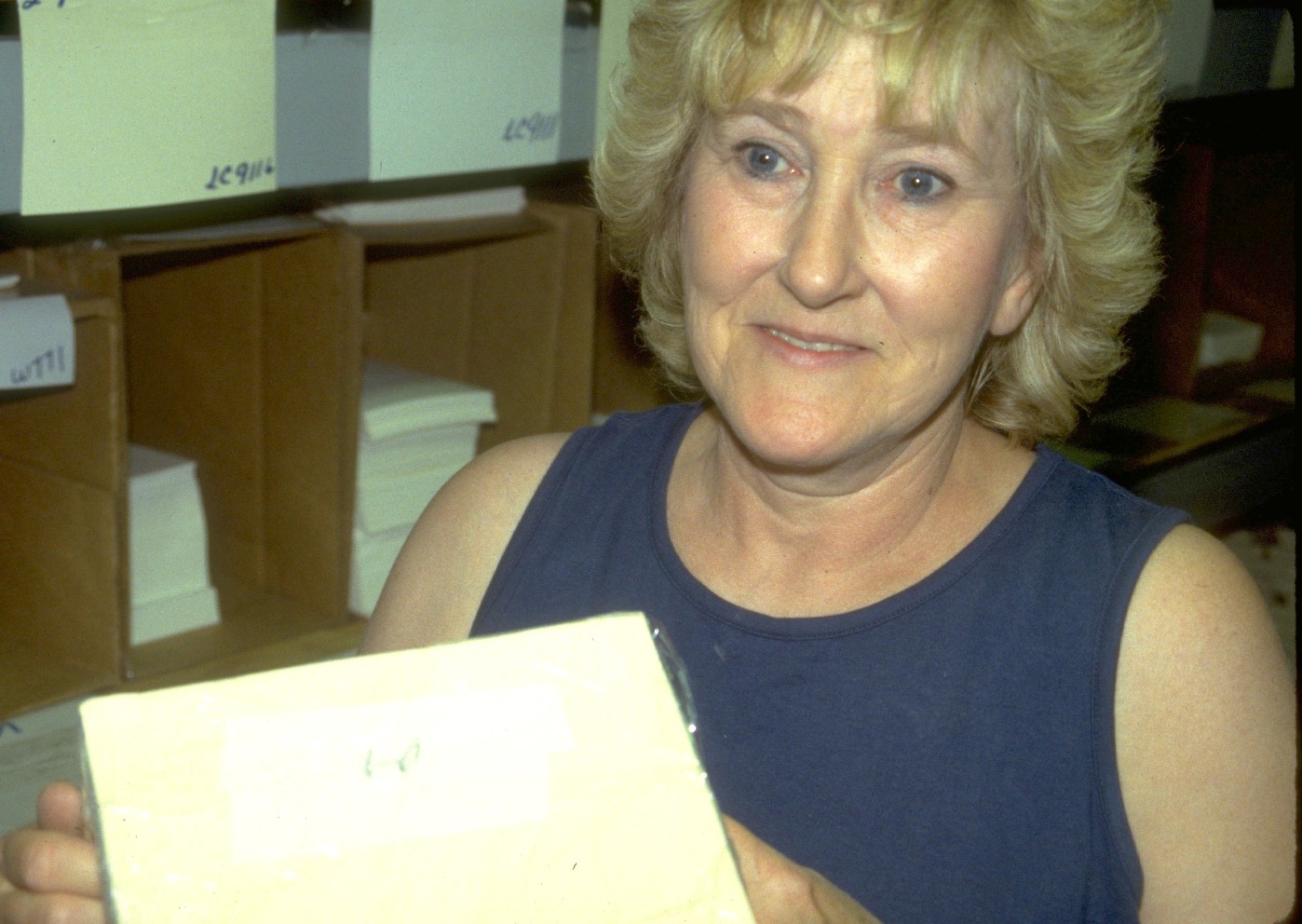

The final example from this plant involved an employee who invented a device to improve a manual ribbon tying task. She made a prototype at home on her kitchen table, which engineers used to create a more polished device. Hand problems dropped and productivity increased about 40%.

|

| The inventor |

One of the rewarding aspects of setting up a workplace ergonomics process is creating a culture where employees feel empowered to use their creativity.