Job Rotation System

Report to XYZ Co.

Dan MacLeod and Eric Kennedy 1993

www.danmacleod.com

Warning!

Ever since I placed this article on this website,

it has received more hits than any other page. However, I think it is the least important

page on the site.

To be sure, there is a time and place for job

rotation and under certain circumstances the system can work well. But

it is a mistake for you to only consider job

rotation as a solution to problems.

Job rotation alone does not change the risk factors present in a

facility. Moreover, it does little by itself to stimulate

innovation and efficiency.

Finally, job rotation might seem like an easy way to reduce the risk of

musculoskeletal disorders

(MSDs), but to do it right can take a lot of work.

If you linked to this page from a search engine, be

sure to visit the home page and learn about

better approaches.

Dan MacLeod

March, 2006

Introduction

There are many reasons for

implementing a job rotation system, including the potential for

increased flexibility in production, increased employee satisfaction

and lower MSD rates. However, establishing a rotation system that

properly determines job rotations and monitors their safe use is not a

simple task. There are many issues to consider and no official

protocol or methodology to call upon. The successful implementation

of a program requires teamwork from all parts of the organization,

including management, union, medical providers, and especially the

employees themselves.

Many job rotation systems have failed because of

lack of planning and lack of foresight into the problems and

shortcomings of rotation. It can prove more difficult than it might

seem at first glance, since it involves changing the organizational

structure of an entire facility.

The following materials provide systematic guidance for setting up a

rotation system. This guidance should be viewed as a starting point

for further discussion by workplace personnel. Roadblocks

There are two major

categories of roadblocks that are often encountered in setting up a

job rotation system:

Cultural issues

The

first set of difficulties are associated with the challenge of

changing the work structure and not from the job rotation in and of

itself. Examples of problems include:

- Experienced workers not wanting to learn new types of

work.

- Employees not wanting to “lend” their equipment to

others.

- Pre-existing differences in wage levels among employees

whose jobs are to be rotated.

- High-seniority employees who have “paid their dues”

working at difficult jobs may believe that they have earned their

right to easier jobs and may resist going back to more difficult work.

- Practical problems of physically getting from one job to

the next.

Rotation

issues:

The other set of difficulties have to do with

issues surrounding the rotation schedule itself:

-

Difficulties in finding appropriate jobs to rotate to

(for the goal of reducing MSDs)

-

Difficulties for employees in learning the subtleties of

some tasks and thus end up increasing the physical demands.

-

Inability of some employees to be physically able to

perform the most difficult tasks

-

Education and training of workers for new jobs

-

Inconsistency of application

Basic Limitation

Job

rotation alone does not change the risk factors present in a

facility. It only distributes the risk factors more evenly across a

larger group of people. Thus, the risk for some individuals can be

reduced, while the risk for others can be increased. However, there

will be no net change in risk factors present. This can be shown in

the following graph.

When

employees rotate between two jobs the risk exposure can be thought of

as being “averaged.” Job rotation may drop the average to within a

safe level, or raise the whole group in excess of safe limits.

Unfortunately, it is not possible with current knowledge to determine

what the safe limit is. For this reason it is prudent to be cautious

about job rotation. Engineering changes should remain the goal of the

ergonomics program.

More

Limitations

If the jobs being rotated involve the same muscle-tendon groups then

the benefit of MSD risk reduction is lost. Thus, rotation among jobs

that are similar is not appropriate. Situations that are best able to

benefit from job rotation are those where, for example, a wrist

intensive task is adjacent to a back-intensive task.

Additionally, if the rotation is too infrequent, such as a daily

rotation, the benefit may also be lost. Typically, employees should

rotate every two hours. An hourly rotation is probably better and a

four-hour rotation probably the maximum that would provide any benefit

from an MSD perspective.

OSHA Guidelines

The following is excerpted from the OSHA Ergonomics Program Management Guidelines

for Meatpacking Plants:

Job rotation should be used with caution and as a preventive measure, not as a response

to symptoms. The principle of job rotation is to alleviate physical fatigue and stress of

a particular set of muscles and tendons by rotating employees among other jobs that use

different muscle-tendon groups. If rotation is utilized, the job analyses must be reviewed

by a qualified person to ensure that the same muscle-tendon groups are not used.

A "qualified person" is one who has thorough training and experience

sufficient to identify ergonomic hazards in the workplace and recommend an effective means

of correction; for example, a plant engineer fully trained in ergonomics - not necessarily

an ergonomist. In analyzing jobs for rotation, the qualified person must have sufficient

expertise to identify the ergonomic stresses each job presents and which muscles and

tendons are used.

Job rotation can mean that a worker performs two or more different tasks in different

parts of the day (i.e.. switching between task "A" and task "B" at

2-hour or 4-hour intervals). The important consideration is to ensure that the different

tasks do not present the same ergonomic stressors to the same parts of the body

(muscle-tendon groups). There is no single work-rest regimen that OSHA recommends; it must

be determined by the nature of the task.

These excerpts indicate the importance of establishing a formal, documented job

rotation system which carefully matches jobs. This matching system should ensure that

different muscle-tendon groups are emphasized.

Scoring System

For best results, it is

important to quantify or score the risk factors associated with each

of the tasks that are to be rotated. There is no established system

or protocol for these scores and you will need to select or develop a

system that is appropriate for your site and the tasks in question.

Typically, a score would be calculated for each job

for (1) the hand and wrist, (2) the arm and shoulder, (3) the lower

back, and (4) the overall job difficulty. However, other factors and

body parts may need to be taken into consideration depending upon the

tasks.

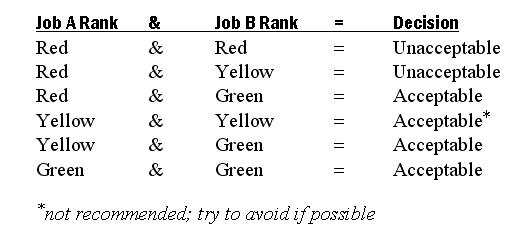

Whatever scoring system is used, it can be helpful to convert your

final results into “red,” “yellow,” and “green” to represent high,

medium, and low risk. Thus, a good rotation would a job with a red

score for the lower back and one with a green score for the lower

back.

Be Systematic

To

realize the beneficial aspects of job rotation it is necessary to

establish definitive internal guidelines that insure consistent

application and at the same time allow for restricting employees from

rotating into jobs they cannot perform. To ensure that all job

rotations meet basic ergonomics requirements a consistent and

systematic approach is required.

It is

probably best to start slowly at first, such as in a pilot work area

so that the program can be further refined before being implemented

elsewhere.

Steps for Implementation

Step 1:

Hold an employee meeting to

determine interest and gain involvement and input. During this

meeting it would be appropriate to have a short presentation on

ergonomics and job rotation. The purpose here is to build upon the

ergonomics training already received and further it by discussing the

relationship between it and job rotation. At this time it would be

appropriate to issue a Job Rotation Questionnaire (see below).

Step 2:

Calculate the scores for the jobs considered for rotation. Use these

scores to establish which jobs should be rotated with which. In

general, decisions about the suitability of a particular job rotation

should be based on the following:

Step 3:

Apply a common-sense review to ensure that the logistics of the

proposed rotation are suitable and that the job rotation seems

reasonable. Also, review the job rotation scheme with the affected

employees. The employee concerns and insights should be taken into

account. If necessary, changes to the list should be made, and final

approval for the list obtained.

Step 4: Provide employees with any

training that they may need to perform the tasks or handle the tools

and equipment. In general, experienced employees going to a new job

should receive the same training requirements and documentation that a

new hire must have before starting in that position.

Step 5: Provide employees with adequate

break-in time to ensure that they are fully qualified and physically

conditioned to perform their new tasks. Similar to training

requirements, the same guidelines for new hires starting out should

apply to experienced employees starting in a new job. Even if the

employees have performed the job previously, they should generally be

allowed the break-in period to become accustomed to the work again.

The training and break-in period enables the

employee to develop those subtle work techniques needed to perform the

task the easiest way and thus minimize the risk factors. This also

suggests that the number of jobs included in a particular rotation

should be kept to a minimum, perhaps two or three, allowing the

employees to become “experts” at each task.

Step 6: Begin job rotation.

Step 7:

Monitor the new rotation to ensure flexibility and consideration for

individuals that are having difficulty performing new tasks. Assess

if further training, break-in, and/or accommodations can be made for

these individuals.

Step 8: Hold follow-up meetings with

employees to evaluate the job rotation. Survey the employees using

the job rotation questionnaire again. Compare results to the initial

survey. If results are favorable then continue rotation. If results

indicate a problem then decide if corrective action is needed or if

rotation should be discontinued.

Step 9:

Track other measures such as injury rates, turnover, employee

satisfaction, or workers compensation to determine effects of the job

rotation.

Comments

These steps should be

viewed as options and starting points for further discussion by the

site ergonomics team and other interested personnel. This framework

was written with a particular company and industry (meatpacking) in

mind, and you may have different needs and applications. The

objective here is to show you one approach for developing a formal,

consistent, and systematic method of job rotations that are based on

the requirements of the jobs.

To

help you make sure that all of the steps of the process are completed

and documented, you may find it helpful to use the Job Rotation

Checklist found on the following page.

Role of Ergonomics Team

Anyone should be able to suggest job rotations, including supervisors,

production employees, or union officials. However, the job rotation

scheme should be approved by TeamErgo with input from the affected

employees before being implemented.

Job Rotation Checklist

The following must occur for each job rotation set-up.

Jobs proposed to be rotated are:

___________________________________

___________________________________

___________________________________

___________________________________

__ Has an employee meeting been held to determine interest and gain

involvement and input?

__ Has each task involved in the

proposed rotation been reviewed with the Physical Job Analysis checklist

to determine precise requirements and has a Job Rotation Worksheet been

generated?

__ Has common sense been used in evaluating

job rotation possibilities?

__ Have all employees involved

in the rotation schedule been trained to do all tasks?

__ Have all employees been

provided an adequate break-in priod to insure they are:

__fully qualified to do all

tasks?

__physically conditioned and

accustomed to do the job?

__ Have flexibility and

consideration been given for individuals in the rotation schedule? Are there any employees

who would have physical difficulty in performing all the tasks? Can accommodations be made

for these individuals?

__ Have formal follow-up evaluations using the Ergonomics Team and supervisors been conducted?

__ Are benefits or problems being tracked (increased or decreased injury rates,

turnover, employee satisfaction, workers compensation costs, efficiency,

quality, etc.)?

Base Line Rotation

Questionnaire

Name: ___________________________ Date: ___________________

Department: _____________________________

Job Title: ____________________________

1. Are you currently rotating jobs?............................ Yes No

If no, go to the next question.

If yes:

a. Do you like it?........................................ Yes No

b. If no, why not?

_________________________________________

c. To what jobs do you rotate?

_______________________________________

___________________________________

___________________________________

d. How often do you rotate? 1/2 hour hourly two hours Other ____________

e. Have you received appropriate training for the jobs that you

rotate to? Yes No

2. If you answered no to question 1:

a. Would you like to rotate?........................... Yes No

b. If no, why not?

________________________________________

c. If yes, to what jobs would you like to rotate?

___________________________________

___________________________________

___________________________________

3. Please stop and fill out the Discomfort Survey form!

4. If you indicated on the form that you were having discomfort, have you seen the

nurse?

5. Are there any other comments that you would like to make?

|